Hanging tank – Milan

Securing access/exit elevation and tank.

Plant: Vertical track, staircase with integrated track and curved landing, “ALU12” anchor points, confined space rescue crane with floor-fixed base and guardrails with landing gate

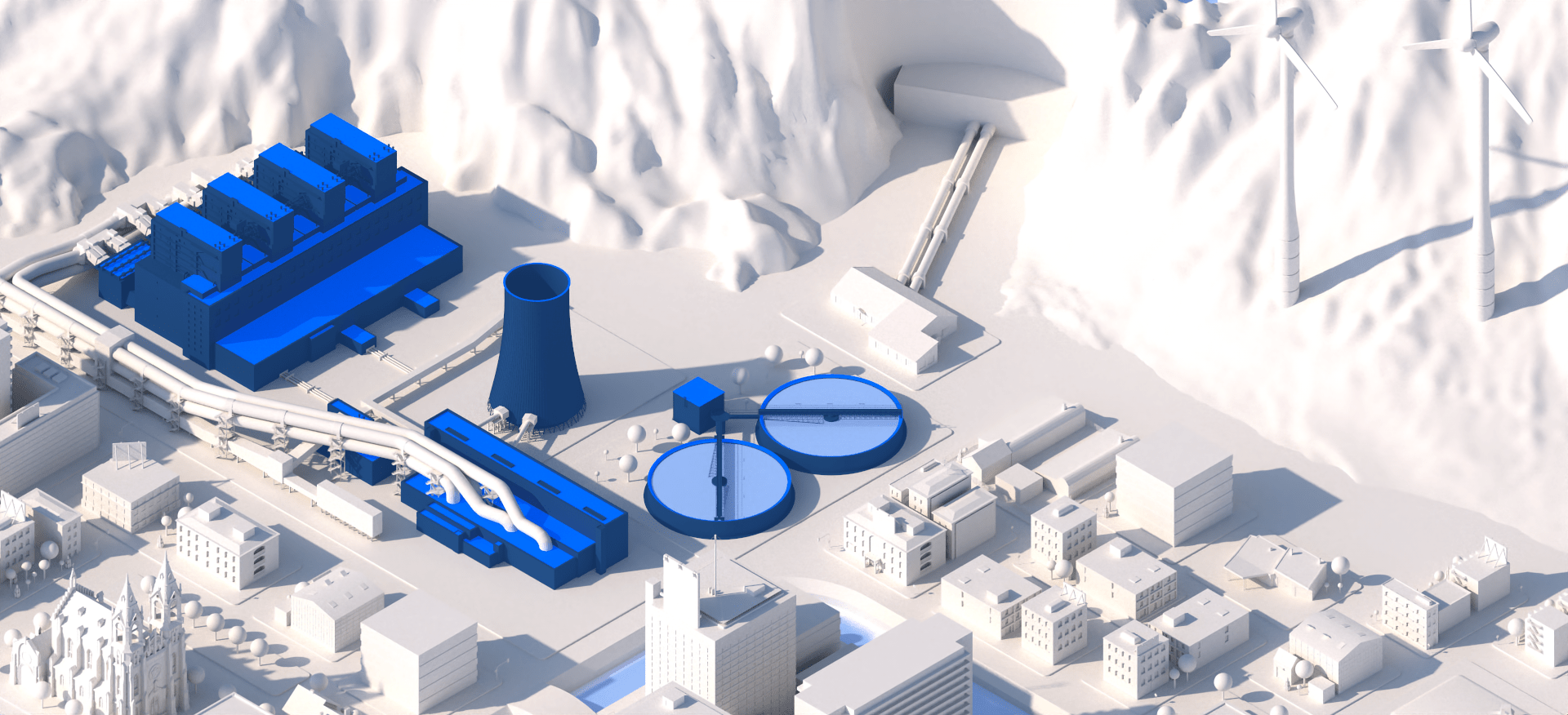

In our area, all drinking water that reaches homes comes from underground aquifers and is drawn through wells.

In our area, all drinking water that reaches homes comes from underground aquifers and is drawn through wells. In addition to the well, the aqueduct consists of the potabilization plants, which, if necessary, treat the water to clean it of pollutants or impurities; reservoirs, which ensure that the water has the right pressure and are reserves to be used in case of need; and the distribution network, through which the water reaches users.

Tanks

They are artificial reservoirs intended for the temporary storage and subsequent controlled release of water according to the demands of the downstream water system. There are three main functions:

- regulate inlet flow rates so as to obtain outlet flow rates appropriate to demands;

- ensure water availability for emergencies;

- determine the pressure in the downstream hydraulic network, releasing them from those in the upstream network.

The primary benefits arising from the use of reservoirs include, for example, lowering the costs of the upstream hydraulic system, which can be sized for lower flow rates; they allow for increased reliability in water supply, as it provides a reserve in case of failure in the upstream hydraulic system; and finally, it allows for the optimization of the operation of lifting and water treatment plants, limiting the variability of their flow rates over time.

Elevated or hanging tanks

They consist of a tank placed at a higher elevation than the ground level by means of a support structure. They are adopted in flat areas to allow gravity feeding of the network. Specifically, the operations to be carried out fall within the scope of Presidential Decree 177. The operation team must consist of at least three people. It is specified that the operations do not pose asphyxiation risks.

PPE to be used

Personal Protective Equipment is defined by art. 74 d. leg. 81/08 as any equipment intended to be worn and kept by the worker for the purpose of protecting him against one or more risks likely to threaten his safety or health during work, as well as any complement or accessory intended for this purpose.

In the case of access to the interior of a hanging tank, the following PPE is provided that constitutes a means of protecting the worker, for example, it is used to protect the respiratory tract so as to prevent inhalation and/or ingestion of aerosols produced.

- Safety boots with acid-resistant nitrile PVC leg.

- Disposable Tyvek overalls and socks.

- Acid-proof gloves, acid-proof goggles.

- Full face mask or hood belt electro-ventilator with ABEK filter or in altenative full face mask, electro-ventilator drawing air from outside atmosphere confined place.

- Harness

- Helmet

Type of operations to be performed

Sanitization programming consists of washing and disinfecting both hanging and underground tanks (underground, semi-inground, and above-ground tanks), desanders, and fiberglass storage vessels. The frequency with which it is performed is generally annually but can also be more or less frequent and dependent on storage if subject to sand or biofilm buildup problems.

As is the case with lifting plants, each plant undergoes the “common inspection,” which is the visual inspection for any abnormalities or malfunctions, and monthly inspection of the relevant area is performed.

Operating Procedures

Procedures must necessarily consider the two types of risks encountered in the operations to be performed:

- Access/exit from ground level to tank elevation;

- Access exit from the reservoir.

Each procedure must take into account both the access mode and the mode of eventual storage. Considering a recent installation at the Cassano D’Adda site, the following solution was studied:

- Installation at the top of the tank, (in the roof cavity) of anchorage, made by crane placed on floor plate, positioned to serve both the ascent to the tank and access to the environment;

- Retractable type device certified EN360 and EN1496 and installed on the crane, equipped with a lanyard for “pulling back” the primary rope, from below;

- Fixed ladder with built-in track system;

- EN 353-1 certified sliding shuttle that can be used on both “shoulders.”

- Rescue kit consisting of:

- “Evacuator” type device with textile rope;

- Ring strap;

- Connectors.

The Crane positioned at the top of the tank can then be used for ascending on the tank, the EN 353- 1 system (escort shuttle) of the ladder can be used in the event of a sickness/fall rescue during access at height. In addition, once at height, by rotating the crane, it can be positioned over the tank access hatch and then used to secure both access and a possible rescue operation.

Training of personnel in charge

Although as mentioned above there is no risk of asphyxiation, we are still in a confined environment so the personnel in charge must meet the following requirements:

- Habilitation to work in confined and/or suspected polluted environments;

- Suitability for temporary work at height;

- Specific training and instruction in the use of installed equipment, including for rescue.

Refresher training should be repeated periodically, according to regulatory guidance but especially according to the work requirements revealed by the specific risk assessment document for the use of safety equipment.