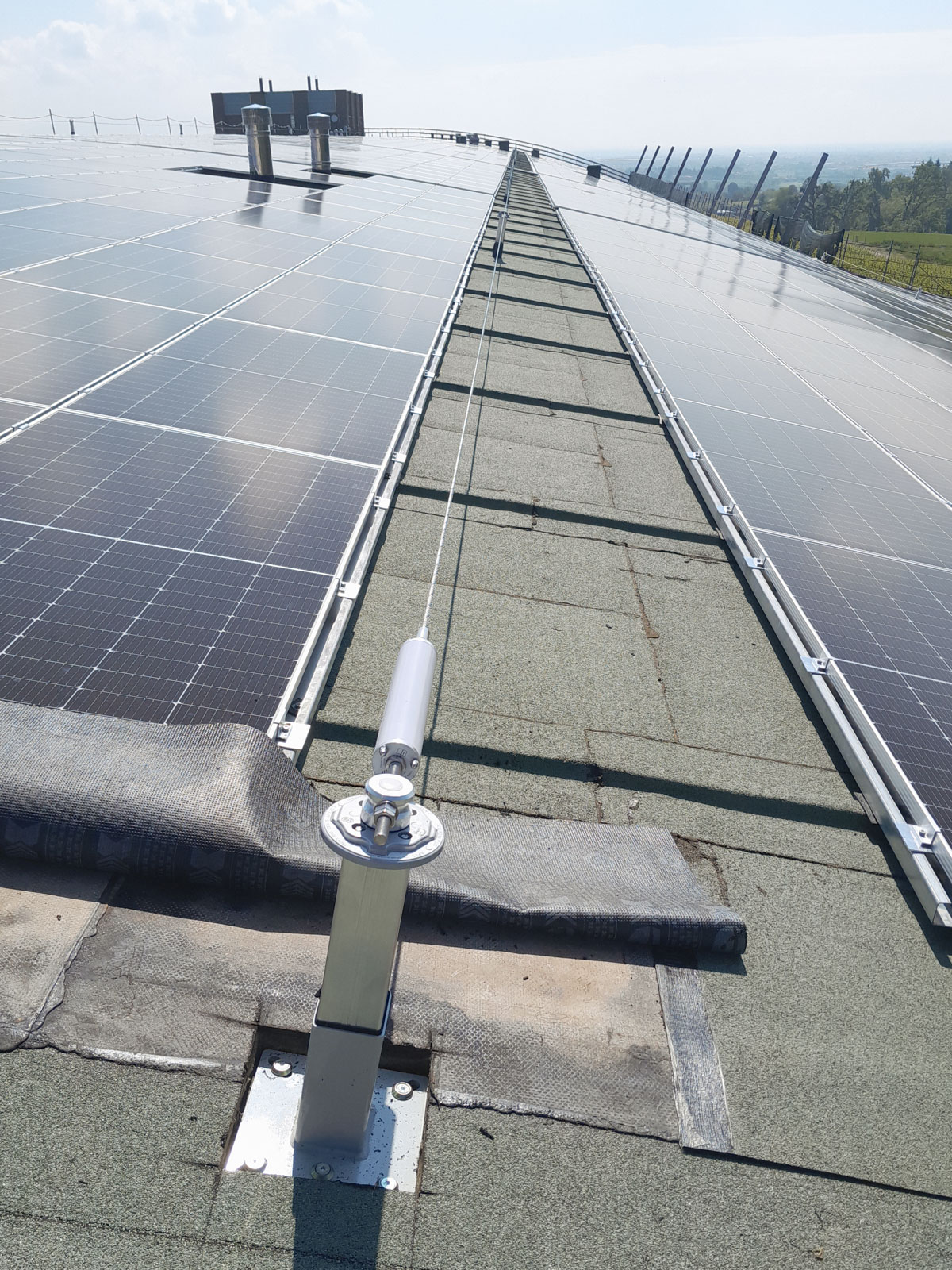

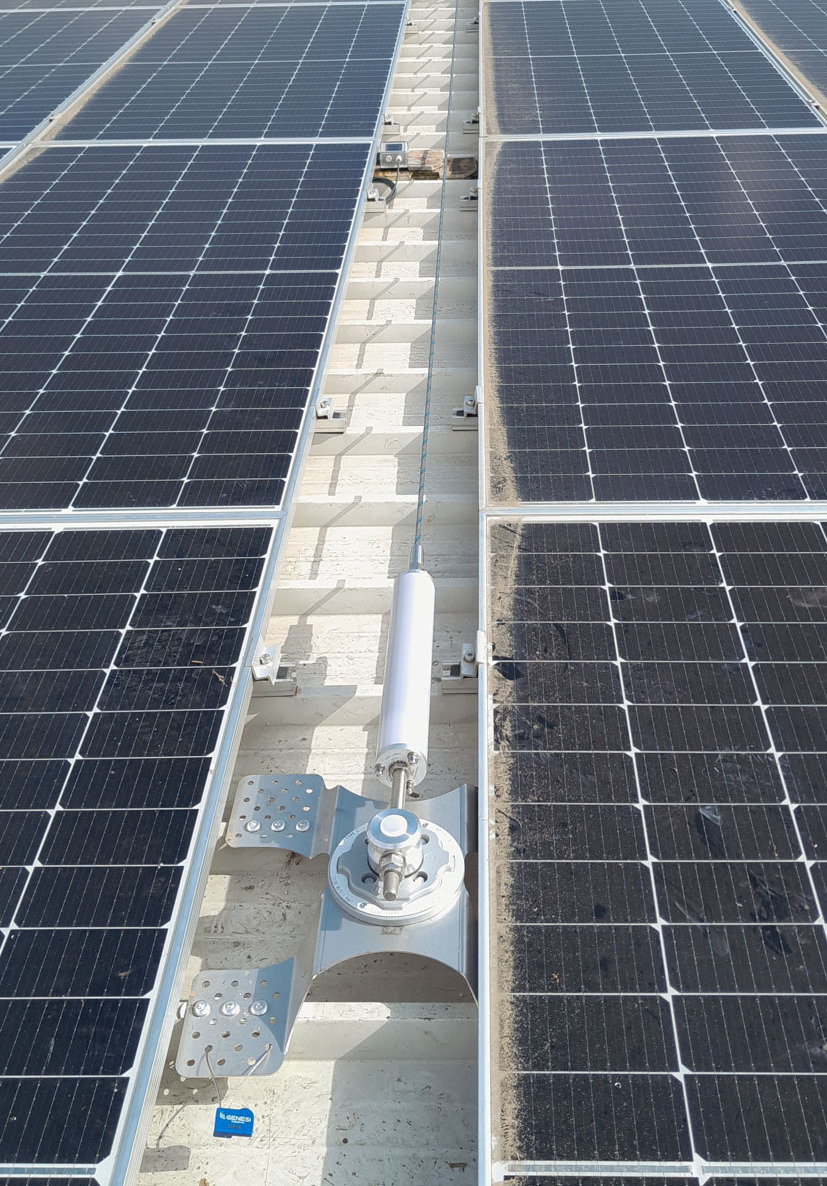

Libera LifelineAnchor device with flexible anchor line.

The LIBERA lifeline is an anchor device that uses a flexible anchor line conforming to the technical standard EN 795:2012 Type C and can be used by 2 operators at the same time, in accordance with technical specification CEN/TS 16415:2013 and by 3 operators in accordance with UNI 11578:2015 (on a rigid structure).

The elements that make up the line are manufactured using a special die-cast aluminium alloy that combines lightness, mechanical and corrosion resistance, and are fixed to the supports using stainless steel hardware.

The absorber assists the tensioner during assembly to allow for proper cable tensioning.

The line is designed for mounting on special aluminium and cataphoretically painted steel supports.

No shuttles are required to use this anchor device: the operator simply hooks the lanyard connector or retractable device onto the line cable: thanks to its shape, the intermediate element can be passed over without the worker having to disengage from the line.

Advantages

High product performance

Reduced aesthetic impact

Adaptable to any type of roof, even low load-bearing capacity

Custom support design

Ergonomy

Lightness

Modularity

Simplicity and easy to use

Ten years warranty

Certifications according to the strictest industry standards

Verification test of proper installation

Components

AP10

Absorber/Turnbuckle

AP-CAVØ8

Cable

AP4

Intermediate element

AP15

End element

AP6

Small arch for corner transmission