Trilob lifelineDeformable lifeline for type C anchorage points.

Deformable lifeline.

The TRILOB TM lifeline complies with the safety requirements set out in standard EN 795:2012 for anchorage devices that fall into type C, i.e. horizontal flexible anchorage lines with a maximum inclination of 15° to the horizontal.

The device also complies with the safety requirements set out in the technical specification CEN/TS16415:2013, which establishes the tests and requirements for devices used simultaneously by several users, and also complies with the Italian standard UNI11578:2015.

The lifeline supports are sized to be mounted on reinforced concrete, wood or steel beams, either directly or with special steel counter plates.

The small size of the elements making up the system and its adaptability make the TRILOB TM line particularly popular for use on buildings of historical and architectural value or on narrow paths with many changes of direction, such as the interior cornices of churches.

In the event of a fall, the intermediate elements deform mechanically, absorbing part of the loads that would otherwise be transmitted to the structure. The intervention of an authorised maintenance technician will check the integrity of the system and restore the elements that have fallen.

The device can be used by 4 operators at the same time and complies with the technical standard EN 795:2012 Type C, the Italian standard UNI11578:2015 and the technical specification CEN|TS 16415:2013; it is covered by a 10-year warranty and subject to annual periodic maintenance.

Components

TRI10

Energy absorber

TRI1

Mobile anchor point

TRI4

Intermediate element

TRI15

Extremity element

Accessories

TRI 15 End element

End element with an articulated head and designed to follow the deformation of the cable in the event of a fall, this movement minimizes stress on the elements of the anchoring device.

Materiale: stainless steel

TRI4 Intermediate element

Intermediate element that in combination with the appropriate mobile anchor device allows safe and uninterrupted passage of the route.

Materiale: stainless steel

TRI100 Mobile anchor point

Movable anchor point that allows intermediate elements and changes of direction to be passed without interruption in the path.

The shuttle can be inserted anywhere in the system, and the EN362 connector, located in the lower housing, prevents accidental spillage.

Materiale: stainless steel

TRI10 Energy absorber

Energy absorber/tensioner block to reduce kinetic energy in the event of a fall by cushioning the impact. It also performs the function of a tensioner for proper cable tensioning.

TRI321 Tensioner

Tensioner for cable locking and tensioning.

Materiale: stainless steel

TRI27 Cable clamp

Cable stop to be inserted into the intermediate when there is a corner or when the line has a length of more than 60 m.

AP-CAV08 Cable

Cable that allows the operator to move safely along its entire length. A blue stranded wire and a Genesi-marked band mark the original cables.

Material: Stainless steel

ADA80 Adapter

Adapter for installation of Trilob line intermediate elements to AP50, AP50C and AP100 poles. It is attached to the pole by 4 self-tapping screws, provided with a washer and EPDM gasket.

Material: stainless steel

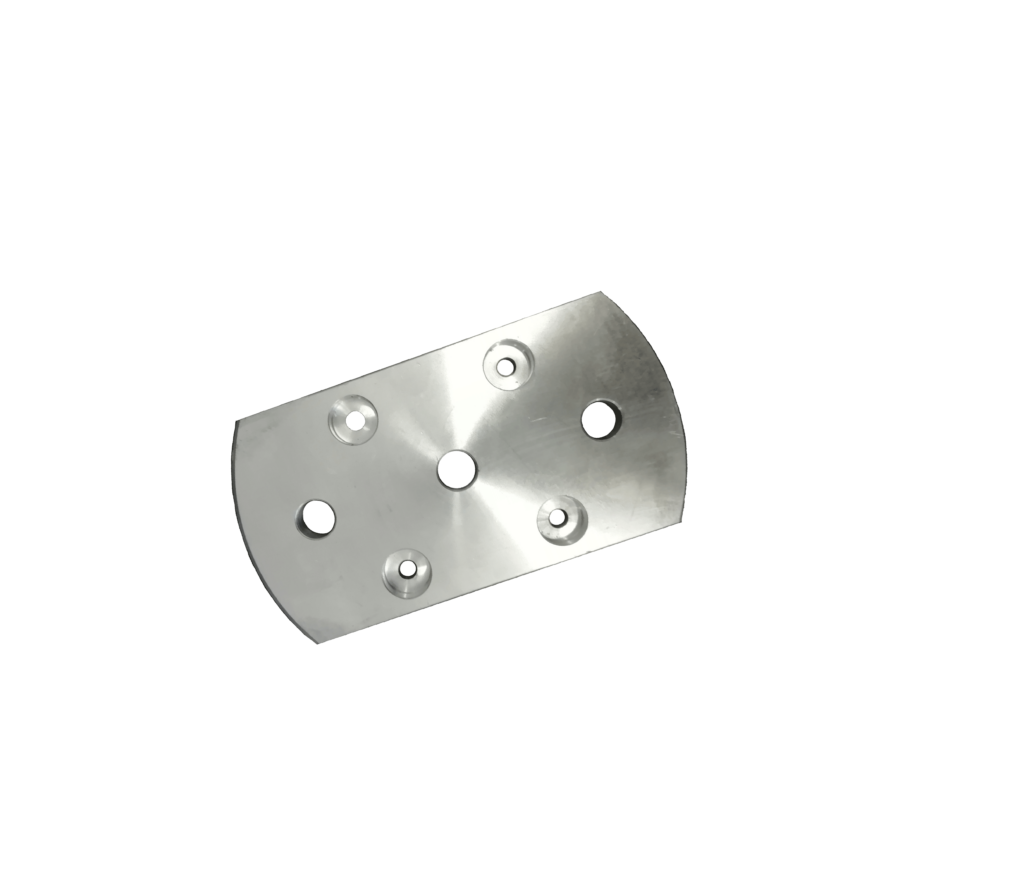

PIATTELLO-SUP Adapter

Adapter for installation of Trilob line end elements to poles with 80×80 mm section.

It is attached to the pole by 4 self-tapping screws, provided with a washer and EPDM gasket.

Material: aluminum alloy

EXA20 Shelf support

Bracket support designed for CLS walls and steel or wooden structures. Bracket with dimensions 170×170 mm and a thickness of 8 mm

Material: cataphorized and painted steel

AP50 Flat base support

It is used as support for all line components. It consists of a pole with a maximum height of 50 cm, adjustable in place, and a socket base.

Material: cataphorized steel base and aluminum pole

AP50C Hut shape base

It is used as support for all line components. It consists of a pole with a maximum height of 50 cm, which can be adjusted in place, and a gabled shaped base for roofs with a maximum slope of 30%.

Material: cataphorized steel base and aluminum pole

AP100 Flat based support

Reinforced flat base support for all line components. It consists of a pole with a maximum height of 100 cm, adjustable in place, and a socket base with a truncatedpyramidal side surface.

Material: cataphorized steel base and aluminum pole

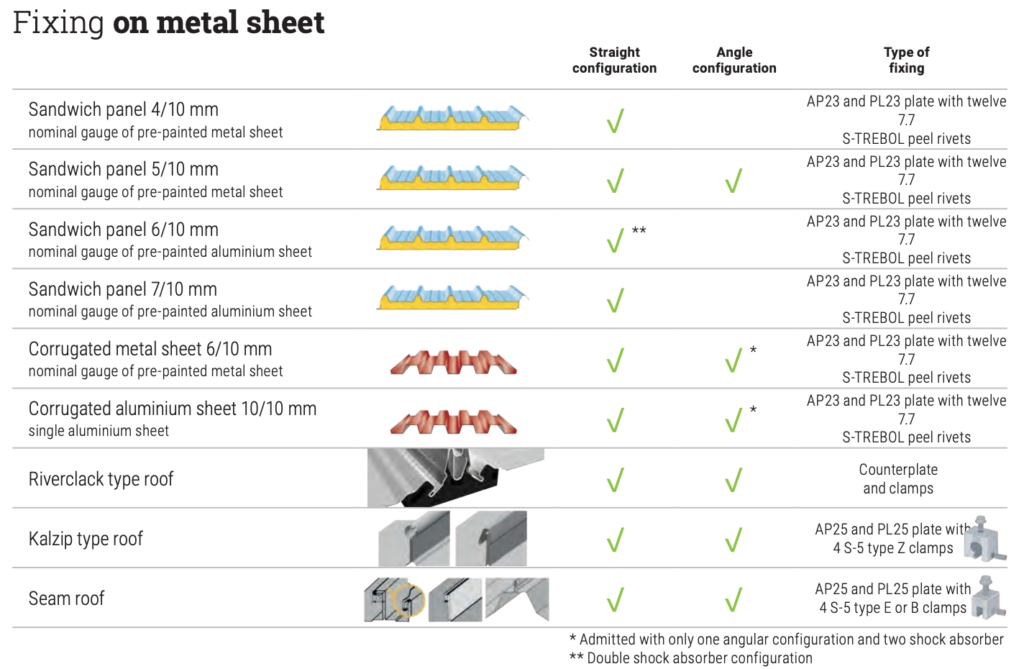

PL23 Plate for corrugated metal sheet

Corrugated sheet metal plate adaptable to different corrugation pitches, from 240 to 390 mm.

Material: stainless steel

PL25 Plate for seam roof

Standing seam plate adaptable to different pitches of the fretwork, from 350 to 610 mm, attaches using 4 S-5 clamps with clamp type E, B or Z.

Material: stainless steel

Clamps

CP-AP Coounterplate

Counterplate CP-AP designed for the application of AP100, AP50 and AP50C supports.

Material: cataphoretic steel

Mounting modes on sheet metal

Advantages

Approved for use by up to 4 operators simultaneously

Large spacing between static restraints, up to 15m

Possibility of direct attachment to structure

Adjustable starting element

Possibility of creating a “closed loop”, with maximum spacing between elements of 4m

Guarantee of constant tension over time, thanks to the plate with inserted SIM card absorber block

Deformability of intermediate elements in the event of a fall

Possibility of making the corner loop without the need for a crimping machine

Simplicity and speed of installation

Reduced loads on structures in the event of a fall

Stamped AISI316 stainless steel elements

Customised design of supports

Minimal aesthetic impact

Ergonomics

Lightness

Modularity

Ten-year warranty

Certifications according to the strictest industry standards

Testing to verify proper installation